SERVICES

Noor Diamonds LTD has a equipped cutting facility based in the company’s London office able to process rough diamond with expert polisher , the leading rough diamond planning system. This provides precise instructions to ensure the best yield with excellent weight and symmetry for every diamond wherever possible. We have additional equipment to then process the rough.

For example, with fancy-shape or old cut or European cut diamonds, our polisher can cut with bruting machine, capable of cutting a perfect girdle with zero deviation in symmetry.

Services

Cutting clients’ rough diamonds (valid Kimberly Process Certificate required).

Re-cutting and remodelling of polished diamonds.

Repair work on damaged or burnt stones.

Cutting Accordingly CAD Design

Trimming work – to ensure stones precisely fit a mount.

Repair Rose Cut/ Old Cut/ Fancy Diamond/Round Brilliant/You Name it

Remodelling From Old cut to Morden Cut

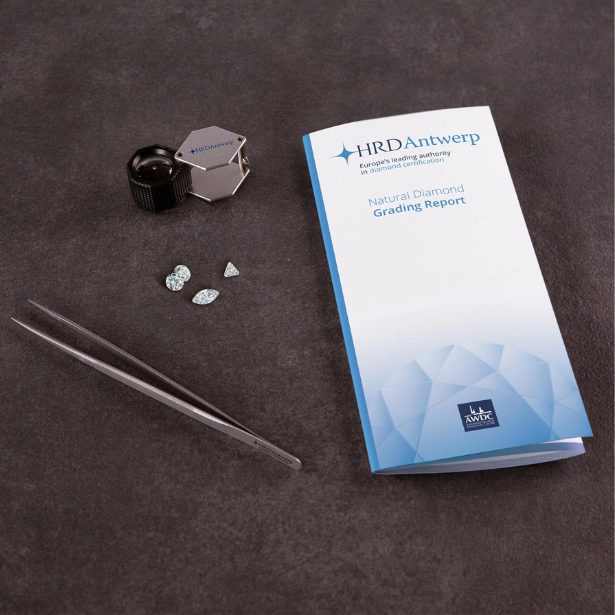

Pre- and post- ‘certification’ work – GIA, HRD, IGI or to comply with a laboratory’s instructions to improve a grade.

What We Do !

Diamond Chip

There’s been a growing crowd of people emerging in recent years requesting services for chip diamonds. This comes as no surprise here at NOOR Diamond Cutter/Polisher, as we find there is always a something new – or old! – to discover with diamonds! Interestingly, a recent trend has been the use of modern machinery for diamond works and cutting, and we’ve seen some beautiful results with Less weight of Losing.

Diamond Polish

Definitely one of the most popular services. Serious collectors or everyday couples go through the mishap of their diamonds losing their brilliance of their stone whether it be exposure to heat or damage. We will re polish your diamond to bring back the brilliance. Like Nothing ever happen.

Diamond Re Cut

Accidents happen, and diamonds are not any different. If your diamond needs re cutting, we are the people you need to talk to . Sometimes diamonds have multiple chips, and need to be re faceted entirely. Please contact us for an estimate.

Rough Diamond Works

If you have a rough diamond that needs faceting and polishing, you have found the right place and person for the job!

Boiling Diamond

Regular boiling is intended to remove external dirt only, and is conducted at various stages of the polishing process as the polisher determines necessary to continue the process. Boiling is done is special rooms.

Special test tubes are set up in special ovens, into which diamonds are placed. If the stones are large, they are put in individually; if the stones are small, they are placed in packets. Sulfuric acid is poured into the test tubes along with a potassium chloride mixture. Diamonds are not affected by acid and are therefore not harmed. The diamonds are then “boiled” for about 15 minutes, until the potassium chloride dissolves and the liquid turns yellow.

The diamonds are then removed from the oven, cooled, washed with a great deal of water, and then with spirit and tried well with cloth towels. At the end of the process, the diamonds are sparkling and bright, clean from any remaining external dirst.

-

Cutting & Polishing

-

Jewellery Manufacturing

-

Stone Mining

-

Cutting & Polishing

-

Jewellery Manufacturing

-

Stone Mining