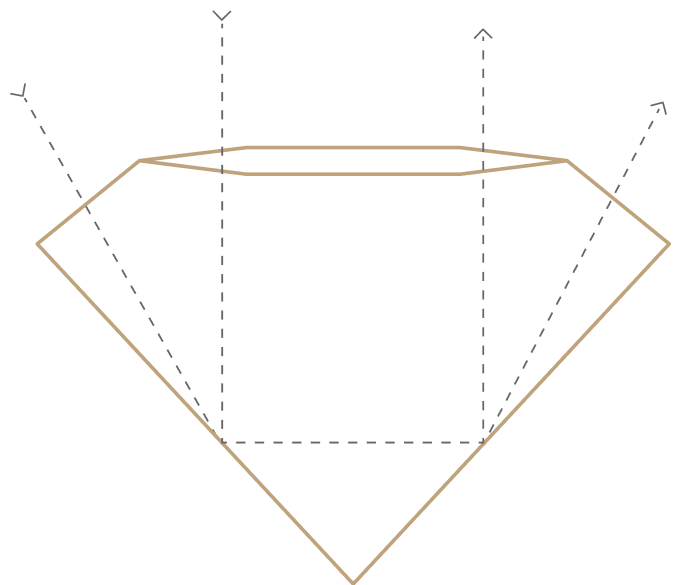

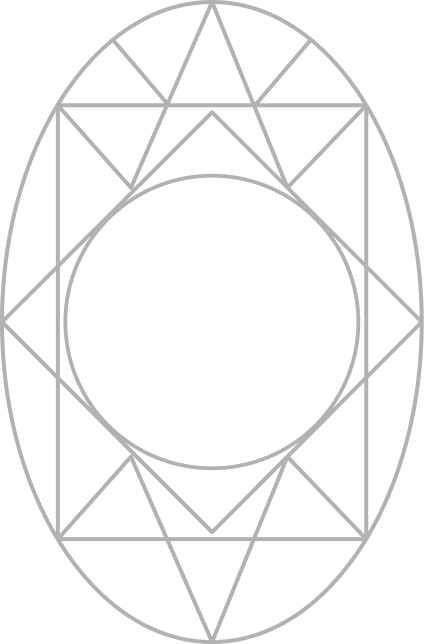

1. Cut

Well cut

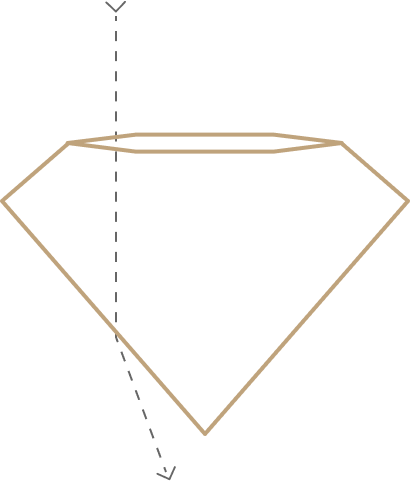

To Shallow

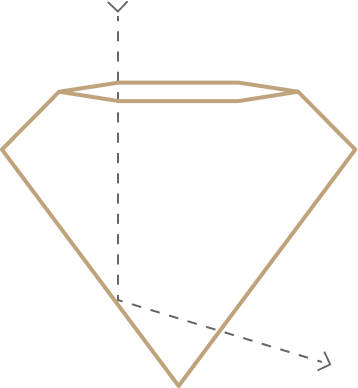

to Deep

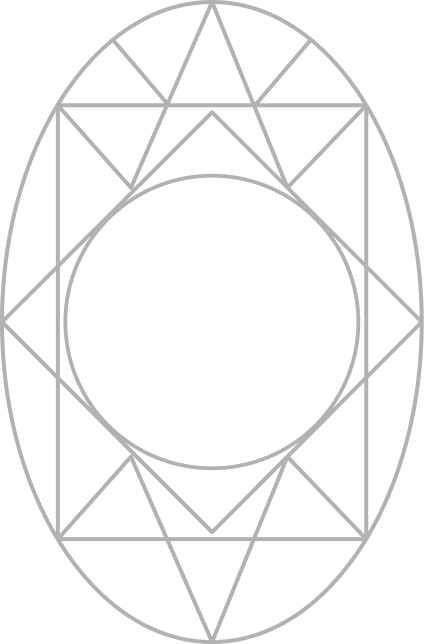

Colourless

Near Colourless

Point Yellow

Yellow

2. Colour

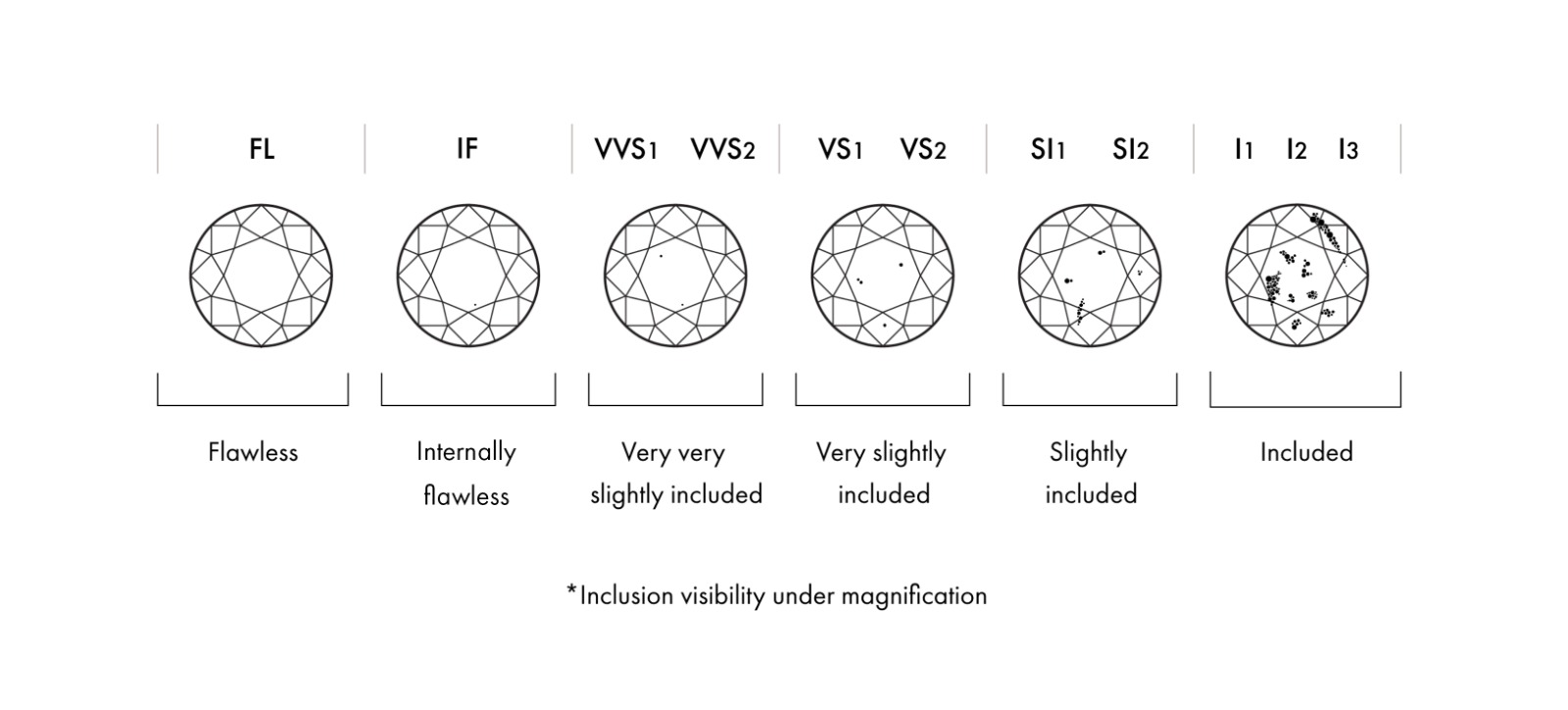

3. Clarity

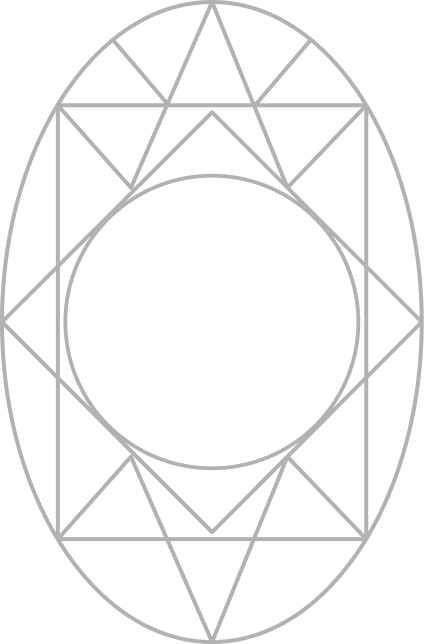

2.00 ct

1.75 ct

1.50 ct

1.00 ct

0.75 ct

0.50 ct

4. Carat

1. FOLLOWING INSTRUCTIONS

A rough diamond will undergo a mapping process before being cut and polished.

A rough diamond is first analysed and mapped by a state-of-the-art diamond mapping machine. The results of which are handed to the diamond cutter where he/she will follow the strict instructions from the diamond assessor, who evaluated the stone. This will usually entail the layout as given by the stage lens of the machine; the modern piece of equipment will determine the specific style, shape and cut of the diamond. For a diamond cutter the scanning process will define two parts of the diamond:

Part A: This specific part of the rough diamond will determine the main portion of the stone.

Part B: The secondary part of the rough diamond

As soon as the cutter receives the mapping results, he or she will define their cutting and polishing plan in order to maximise the potential of a rough diamond. There is always a trade-off. The same rough stone can be cut in a number of ways, each yielding a different outcome. While some cut diamonds just for their size, a skilled diamond cutter will cut a diamond to maximise its true brilliance – here, size is secondary to the quality of the cut which will affect the overall fire, brilliance and scintillation of the diamond. A craftsman will then mark the diamond with ink to indicate where the diamond will be cut. The cutter will then use a diamond tool called a tang to polish the stone. Depending on the size of the diamond the cutter would possibly have to undergo a cleaving or sawing process to first separate the rough diamond.

2. MARKING OF THE DIAMOND

A craftsman will mark the gemstone with ink to indicate where the diamond will be cut.

3. CLEAVING OR SAWING

To separate the diamond in two pieces it will be cleaved or sawed.

During this process, the diamond cutter will cleave or saw the rough diamond into two separate pieces. In this case, the diamond is either cleaved or sawed depending on the different growth planes on the stone. The stone is cleaved if the marking is along the line or parallel with the diamond. If the marking is against the line, then it needs to be sawed using a laser – a fast and accurate way to cut a diamond in two using the latest technology.

In order for a master cutter to turn a rough diamond into a beautiful faceted gemstone with fire, brilliance and scintillation they have to undergo the polishing process. This step in the process takes extreme precision and years of experience for a cutter to perfect. First, the talented cutter will place the diamond on a rotating arm, called a tang, and put it against a spinning wheel, called a scaife; this way the rough stone will be polished into a smooth and gleaming gem. After, the polishing process the diamond will go through two other important steps:

Blocking

Blocking is another important step a cutter will take in the polishing process – during this step the cutter will polish the facets onto the diamond laying the foundations of the stone. In other words, the blocking stage is when the symmetry of the stone is established by creating the set of facets on the table, crown, pavilion and culet. Once the blocking stage is complete, the stone is often referred to as a “single cut” diamond.

Brillianteering

The next step and final step in the diamond cutting and polishing process is to polish the remaining facets in the brilliant cut diamond. At the end of the process, a round brilliant cut diamond will have 57 facets, all of which need to be cut in perfect proportion and symmetry to achieve maximum brilliance. If a diamond is cut too deep or too shallow, it will leak light and result in a loss in brilliance.

4. POLISHING

Polishing a diamond takes extreme precision and years of experience for a cutter to perfect.

Once all 57 facets are polished, the diamond will be sent for inspection. If it doesn’t meet the standards of a brilliant cut diamond, the stone will be sent back to the cutter to correct. But, it is essential that they get the process right the first time as you cannot replace what you have polished. Each correction made, results in a loss of diamond weight which affects the overall value of the diamond

In the end a diamond cutter is responsible for giving you a diamond with maximum brilliance that will make you shine forever. A day in the life of a diamond cutter requires dedication, attention to detail, artistic vision and a complex set of instructions in order to polish a diamond to reach its full potential. Next time you look at your diamond, take a moment to consider the years in training and expert skill mastered by a diamond cutter.